Status 09/2010

dispersed by the effect of heat escapes before the

floor covering is laid. The heating system installer

must hand over a report about the specified heating

and cooling measures performed in this respect as

per

"Schnittstellenkoordination

bei

beheizten

Fußbodenkonstruktionen"

[interface

coordination

with heated floors"], published by the

Zentralverband

Sanitär Heizung Klima

(German association for

sanitary fittings, heating and air conditioning). A

moisture test may only be carried out at the

measuring points marked by the screed installer.

If

no measuring points are available, the floor installer

must submit his reservations to the client in writing.

10

Conductive installation

This

type

of

installation

involves

laying

the

conductive floorcovering on a conductive system

that

should

be

incorporated

in

the

additional

electrical

safety

measures

by

means

of

an

equipotential bonding system.

In rooms to which the relevant guidelines of the

professional association do not apply, connections

for example to neutral conductors are possible.

The

conductive flooring needs to be earthed by an

electrical fitter.

When installing conductive DLW Vinyl Conductive /

ESD sheet flooring, standard commercial, non-

conductive PVC adhesives can be used.

An exception to this is when installing on very dry or

insolating subfloors, for example on chipboards, dry

screeds, mastic asphalt, underfloor heating or

subfloors or dry screeds treated with epoxy resin

primers.

With these subfloors, a conductive adhesive

must be used.

When installing conductive DLW Vinyl

Conductive / ESD tiles, a conductive adhesive must

be used for bonding.

.

The Armstrong DLW advice service on +49 (0) 71 42

/ 71 - 8 45 would be pleased to help with queries on

conductive installation.

The recommended conductive system is:

10.1

Installation

on

copper

tapes

Each row of tiles/strip of floor covering must be

linked crosswise with a continuous copper strip.

Individual rows/strips must be at least 3 m² in size

and linked to the rest of the area with a copper tape.

In rooms of up to 40 m², connection points for

equipotential bonding should be provided in at least

one point in the room.

In larger rooms, several

connection points must be used.

When installing tiles, a conductive adhesive must

always be used. One strip of copper tape per 40 m²,

laid approx.

1 m under the floor covering, is

sufficient.

We offer conductive tape for the installation of DLW

VINYL Conductive / ESD, available as 50 m rolls.

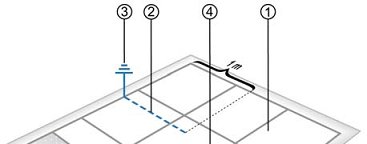

1.

DLW Vinyl Conductive / ESD sheet flooring

2.

Copper

tape

3.

Earth

4.

Subfloor

5.

Top

seam

1.

DLW Vinyl Conductive / ESD tiles

2.

Copper tape approx. 1 m for max. 40 m²

3.

Earth

4.

Subfloor

11

Cleaning and maintenance

The contractor should provide the customer with

written

maintenance

instructions

for

the

floor

covering in accordance with VOB, DIN 18365,

Section C, Paragraph 3.1.4.